Commodity information

Introduction of ultra-low nitrogen emission gas boiler

Full three - dimensional computer aided design calculation

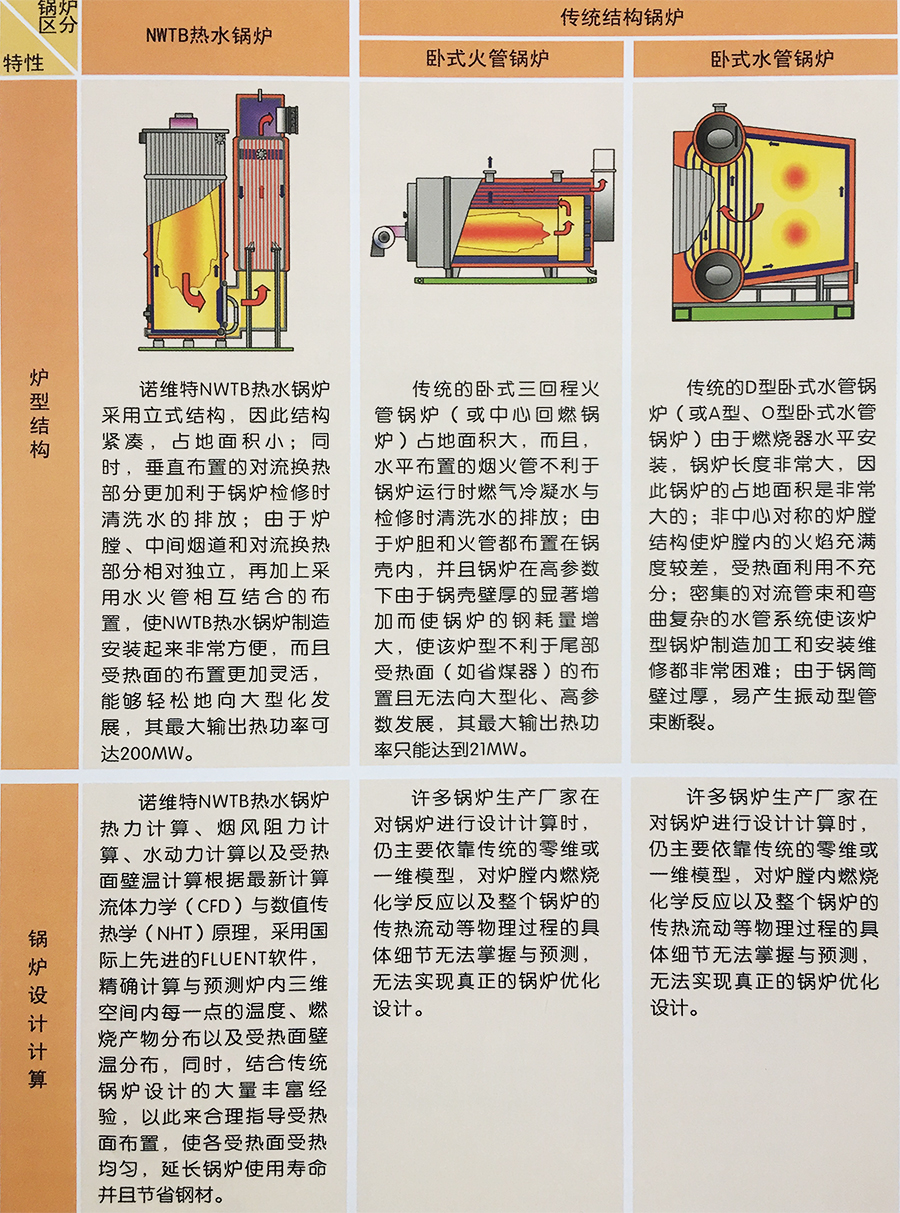

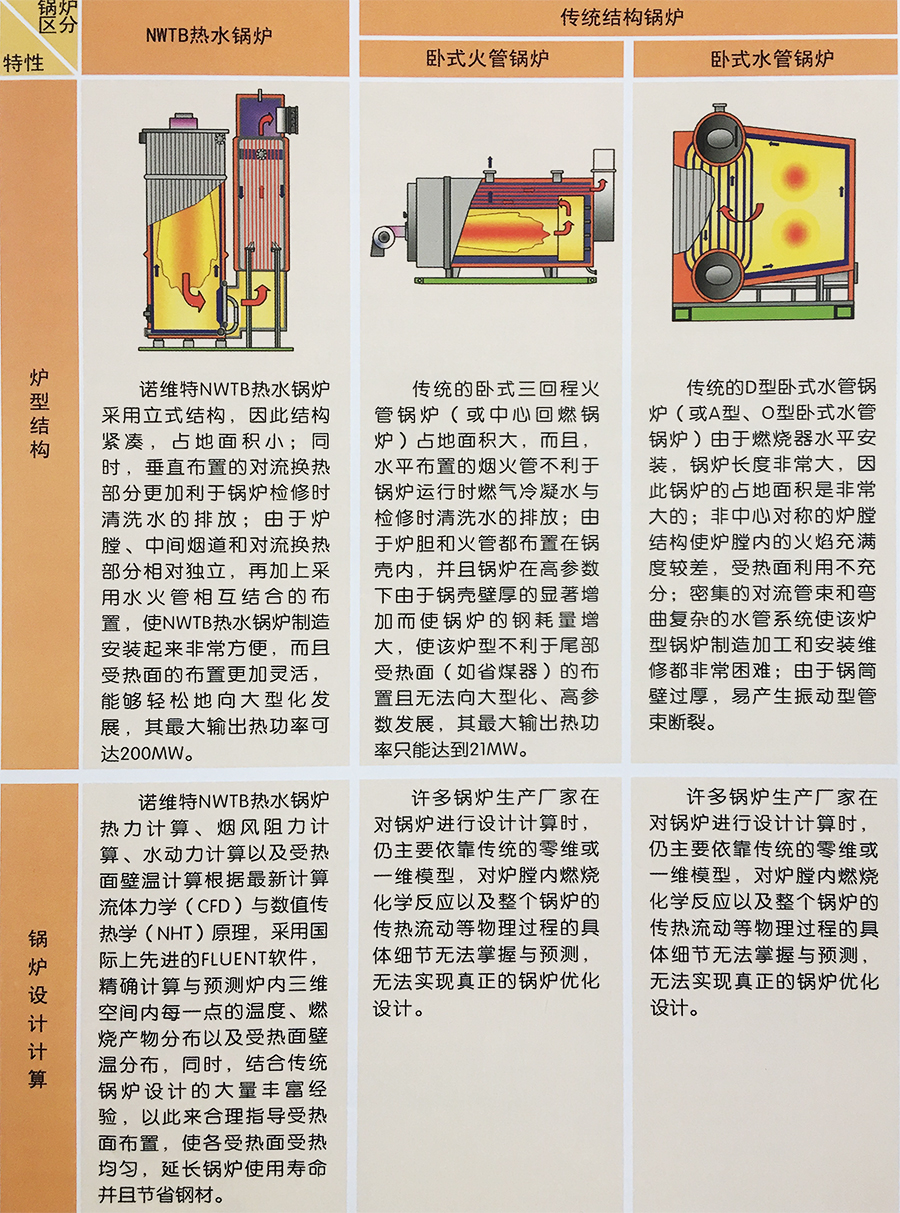

Thermodynamic calculation and smoke wind resistance calculation are based on the latest computational fluid mechanics (CFD) and numerical heat transfer (NHT) principles, using the internationally advanced FLUENT

The software accurately calculates the temperature at each point in the furnace, the distribution of combustion products and the temperature distribution of the heating surface, so as to reasonably guide the layout of the heating surface, make the heating surface evenly, extend the service life of the boiler and save steel;

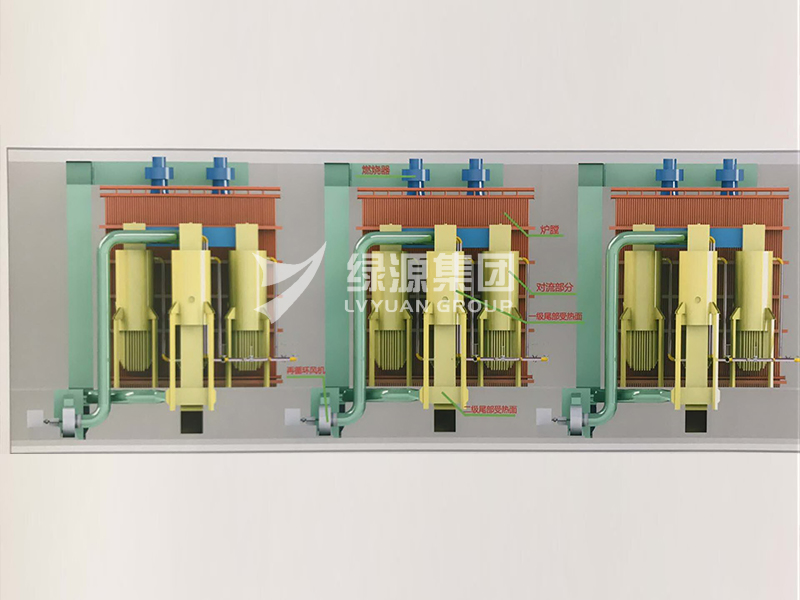

The world's first vertical top blowing U - shaped layout

Because the boiler USES the vertical structure, therefore the structure is compact, occupies a small area;At the same time, the vertical arrangement of convective heat transfer part is more conducive to the boiler cleaning water discharge during maintenance;The u-shaped flue gas flow and water flow are arranged counter-current, which increases the heat exchange temperature and pressure of flue gas and water, reduces the temperature of smoke exhaust and increases the thermal efficiency of the boiler system.

Powerful low pollution emission function

The use of the world's advanced low NOx burner, the use of the latest stage air distribution and flue gas recycling technology, greatly inhibit the fuel nitrogen in the combustion process to NOx transformation;At the same time, the large furnace structure reduces the heat load of the entire furnace volume, which makes the temperature in the furnace lower and inhibits the transformation from nitrogen to NOx in the combustion air.

Efficient heat transfer technology

Because the furnace chamber adopts membrane water cooling wall structure, it can fully absorb the radiant heat from the flame, and improve the sealing of the furnace chamber. At the same time, because the furnace wall is not directly exposed to flame radiation, it can not use refractory materials, so that the weight of the furnace wall is greatly reduced, and the weight of the frame is reduced at the same time.In the convective part, the smoke tube structure is adopted, and a spoiler is arranged at the top of the smoke tube. Due to the presence of spoiler, the disturbance of flue gas is strengthened, the boundary layer hindering heat transfer is destroyed, and the thermal resistance of convective heat transfer is reduced, so the heat transfer between air and water is strengthened.

Forced circulation dc boiler

The water supply of the boiler depends on the water pump pressure to flow through the boiler once, so the cooling of the heating surface can be fully guaranteed. At the same time, the boiler starts very quickly.Because there is no pot barrel and complex piping system and hoisting system, the structure is simple and fluent, which greatly simplifies the manufacturing process and reduces the weight of the boiler, and is convenient for installation and maintenance

Wide range of load regulation

Carefully designed and equipped burner and reasonable radiation and convection heating surface area distribution so that the boiler can be stable operation between 20% and 100% load, and output qualified parameters of hot water;

Technical characteristics

The vertical water and fire tube boiler is designed by MW Power Oy/original Finland novit co., LTD., a professional boiler design company in Finland. The boiler type of this company is based on the design of gas-fired boiler, which overcomes all the disadvantages of converting coal into gas-fired boiler and is the most advanced furnace type in the world today.

Reasonable and compact structure, small area

• before the 1970s, the convection heating surfaces at the rear of large gas or oil-fired hot water boilers in Finland were also in the form of serpentine tube tubes, a traditional structure based on the design of steam boilers.Results during the operation, it was found that the pipes of this structure were easy to be corroded, and no matter what measures were taken, the corrosion phenomenon could not be fundamentally reduced or avoided. Therefore, it was urgent to develop a new structure specially designed for hot water boilers to fundamentally solve the low-temperature corrosion phenomenon.Through a lot of research, the founder of novit in Finland developed the NWTB type hot water boiler, which subverted the structure of the traditional hot water boiler transformed from the coal-fired steam boiler, and the heating surface of the tail of the vertical arrangement of the hot water tube fundamentally solved the phenomenon of low-temperature corrosion.

• the use of advanced three-dimensional design software to ensure that the furnace and any point of the heating surface (such as pressure, temperature, oxygen and flow rate, etc.) so that the heating surface layout of the maximum rationalization, to avoid the flame erosion of the water wall, to avoid the occurrence of water circulation stagnation in the water wall tube reverse flow phenomenon.

• vertical layout, combination of water and fire pipes, minimum floor area.

• bottom support, independent system of platform stairs, no burden of boiler body weight.

• dc forced circulation, no pot, tube and lifting system simple.

Energy conservation and environmental protection

• fully sealed structure, the furnace is a water-cooled wall structure, the convection heating surface is a fire tube structure with a pot shell seal, the boiler surface temperature is low, the heat loss is very small.

• the convection tube is equipped with spoiler to strengthen heat transfer.

• the burner is arranged against the upstream, so that the water and flue gas flow in opposite directions, so that the exhaust temperature can be lower than the outlet temperature, the temperature pressure is high, and the heat transfer efficiency is high.

• large furnace structure makes furnace combustion temperature low.

The service life of boiler is long

• there is an internal circulation pipeline between the outlet water and the return water pipeline of the boiler. When the temperature of the return water of the heating network is lower than 65℃, the mixing pump on the internal circulation pipeline will extract an appropriate amount of hot water from the supply pipeline with high temperature to the return water pipeline, so as to improve the inlet temperature of the boiler and prevent the occurrence of low-temperature corrosion.

• the vertically arranged fire tube generates internal natural circulation to the water side of the heating surface during operation. Naturally rising hot water will increase the temperature of the heating surface at the inlet, which is a double insurance against low-temperature corrosion.

• vertically arranged fire tube convection heating surface, flue gas flow in the tube longitudinal, completely solve the problem of ash accumulation, during the shutdown of the furnace may be generated condensate water will naturally slip and be removed, to avoid the occurrence of corrosion.

• there is no dead Angle of flue gas flow in either the convective heating surface of the furnace or the rear end, ensuring uniform heat transfer.

• one point in the bottom support is fixed, while the rest can slide, so that the boiler can expand freely in the process of thermal expansion and cold contraction, and the boiler does not deform, thus improving the service life of the boiler.

Easy and fast installation

• modular design, furnace and convection parts can be made in the factory after several modules, delivered to the site, saving installation time and costs, and greatly improving product quality.

• no pot barrel, bottom support, no complex hoisting system, no space bend pipe, reducing a lot of site installation work.

High operational reliability

• the convective heat transfer part has a large volume of water capacity, which can ensure the safe and stable operation of the boiler, absorb the working condition changes caused by the fluctuation of the heat network, and ensure the cooling of the water cooling wall of the furnace through the sufficient water flow rate of the boiler, so as to make the operation of the boiler more reliable and safe.

• its burner is located at the top of the furnace for easy maintenance and repair, and is of better safety type.The density of natural gas is lighter than that of air. If there is a natural gas leak, the leaking natural gas will be quickly discharged from the outside by the exhaust fan located on the top of the plant, avoiding the risk of fire.

Therefore, from the point of view of safe operation and convenient maintenance, the far edge of the burner placed on the top of the boiler is stronger than the side layout of the burner.

The safety operation of the boiler and the personal safety of the operators is crucial, corner of the weak NWTB boiler furnace is designed, when chamber pressure is very high due to some reason or the chamber of a stove or furnace deflagration, weak Angle first craze, release the pressure of furnace, prevent the large-scale boiler explosion disasters, which is NWTB boiler design is unique.In addition by the weak Angle instead of the explosion-proof door design, because the boiler is micro-positive pressure combustion, can also enhance the boiler gas seal.

Maintenance is simple and lowest maintenance cost

• the simple structure of the ontology makes maintenance very simple.

• vertical fire tube structure for convection heating surface, easy to clean.

• vertical fire tube structure of convection heating surface, even after long operation or due to improper operation, a few tubes need to be replaced, just pull out these tubes that need to be replaced and install them into a new tube, the cost is very low.

• the burner is located on top of the boiler for easy maintenance and repair.

Product comparison

Sweep WeChat yards pay attention to us

Sweep WeChat yards pay attention to us